Water Turbine Inlet Hydraulic Butterfly Valve

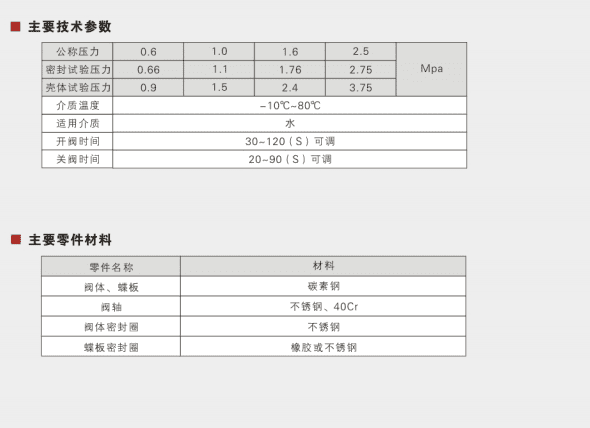

The water turbine inlet hydraulic butterfly valve designed by Dazhong Valve Group has three power sources for the hydraulic system of the valve, namely the oil pump motor unit, the hydraulic energy stored in the accumulator, and the manual oil pump. The butterfly valve adopts double eccentricity. The valve is equipped with two types of hydraulic locking device and mechanical locking device. The valve body and butterfly plate are welded by carbon steel, which has high overall strength and good rigidity.

The turbine inlet hydraulic butterfly valve is the latest product developed by our company in accordance with the basic technical requirements of GB/T14478-1993 large and medium turbine inlet valves. Installed at the inlet of the turbine volute.

The hydraulic system of this valve has three power sources, namely the oil pump motor unit, the hydraulic energy stored in the accumulator, and the manual oil pump. The hydraulic energy stored in the accumulator is the main power source, and the oil pump unit is responsible for charging the accumulator. When necessary, the valve switch can be directly driven. The manual oil pump is used to manually open and close the valve when the accumulator has no stored energy and no electricity.

The butterfly valve adopts double eccentricity and streamlined design, so that the valve has good hydraulic characteristics, the flow resistance coefficient is less than 0.2, and the valve eccentric potential energy and the pressure potential energy of the accumulator are available when the valve is automatically closed, so that the valve always has sufficient Insurance factor. Reliable closing is guaranteed in all circumstances.

The valve body and disc are welded with carbon steel, which has high overall strength and good rigidity. The valve is equipped with two types of hydraulic locking devices and mechanical locking devices to prevent the occurrence of water action when the disc is fully opened. Shake and prevent accidents due to misoperation of valves when overhauling turbines.

This valve has a relatively complete hydraulic and electrical control system. It can be operated locally or remotely. It can easily realize the interlocking program control of the turbine and the valve and the centralized control of the microcomputer.