J961Y Globe Check Valve

The J961Y globe check valve designed by Dazhong Valve Group adopts pressure self-tightening seal. The higher the medium pressure, the better the sealing performance. The sealing ring adopts formed asbestos packing. The valve disc moves up and down, and the valve stem is lifted up before running, and the valve bracket is connected with the electric device, so that the valve can achieve better sealing. The valve disc and valve seat sealing surface are made of drill-based cemented carbide plasma spray welding, and the surface of the valve stem is treated with anti-corrosion nitriding.

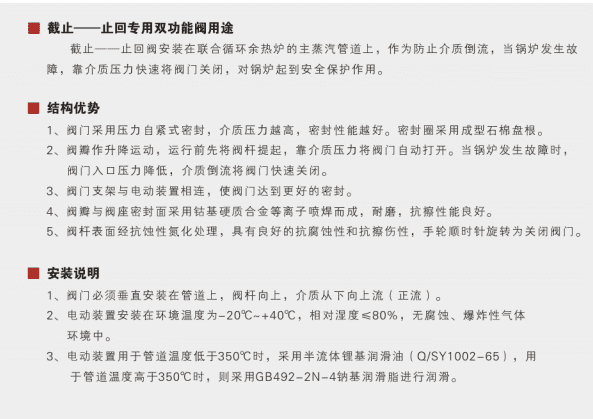

The cut-off check valve is installed on the main steam pipeline of the combined cycle waste heat furnace to prevent the backflow of the medium. When the boiler fails, the valve will be quickly closed by the medium pressure to protect the boiler.

The valve adopts pressure self-tightening seal. The higher the medium pressure, the better the sealing performance. The sealing ring adopts formed asbestos packing.

The valve disc moves up and down, lift the valve stem before operation, and the valve is automatically opened by the medium pressure. When the boiler fails, the inlet pressure of the valve decreases, and the medium backflow will quickly close the valve.

The valve bracket is connected to the electric device to make the valve achieve a better seal.

The sealing surface of the valve disc and valve seat is made of drill-base cemented carbide plasma spray welding, which has good wear resistance and anti-friction performance.

The surface of the valve stem is treated with anti-corrosion nitriding, which has good corrosion resistance and scratch resistance. The handwheel is rotated clockwise to close the valve.