Vacuum Isolation Globe Valve

The vacuum isolation globe valve designed by Dazhong Valve Group is designed and manufactured according to the JB/T3595 standard, and meets the requirements for supporting the use of power station equipment. The vacuum sealing structure packing chamber is designed, the valve stem is quenched and tempered and surface nitrided, the flange gasket is made of composite material, and the inverted seal is made of stainless steel threaded connection sealing seat or body surfacing of austenitic stainless steel, and the sealing is reliable.

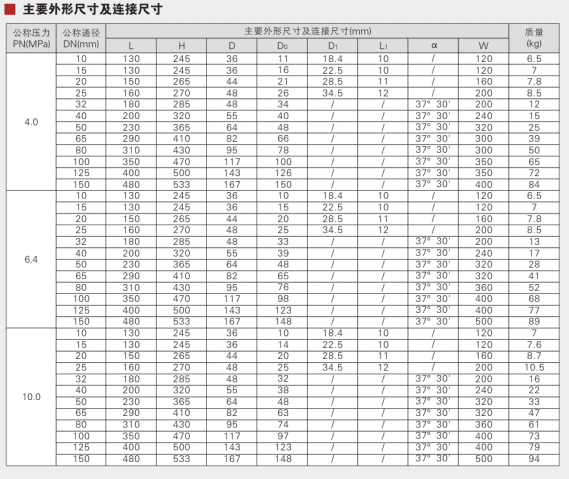

The globe valve vacuum isolation globe valve is suitable for cutting off or connecting the medium in the pipeline with the nominal pressure PN4.0~10.0MPa and the working temperature t≤200℃ of the national water condensing system of the thermal power station. Applicable medium for; water, steam, etc.

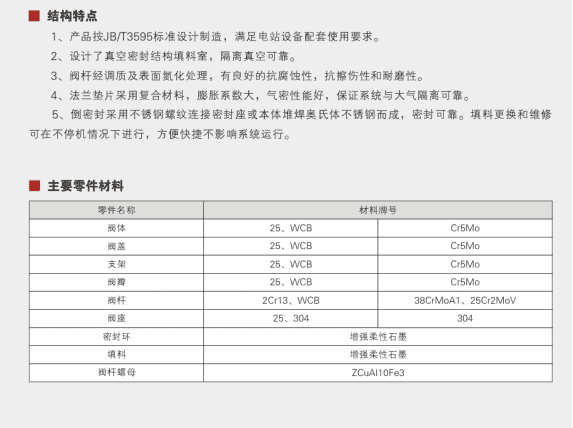

The product is designed and manufactured according to the JB/T3595 standard, and meets the requirements for supporting the use of power station equipment.

Designed with a vacuum-tight structure packing chamber, the isolation of vacuum is reliable.

The valve stem is quenched, tempered and surface nitrided, and has good corrosion resistance, scratch resistance and wear resistance.

The flange gasket is made of composite material, with large expansion coefficient and good air tightness, ensuring reliable isolation between the system and the atmosphere.

The inverted seal is made of stainless steel threaded connection seal seat or austenitic stainless steel surfacing on the body, and the seal is reliable. Packing replacement and maintenance can be carried out without downtime, which is convenient and quick without affecting the system operation.